Level 3 Heat Pump Monitoring Bundle (emonHP)

Pre-provisioned fully inclusive bundle for Level 3 Heat Pump Monitoring. High accuracy (1-2% MID approved) independent monitoring of all air-to-water ASHPs or water-to-water GSHPs.

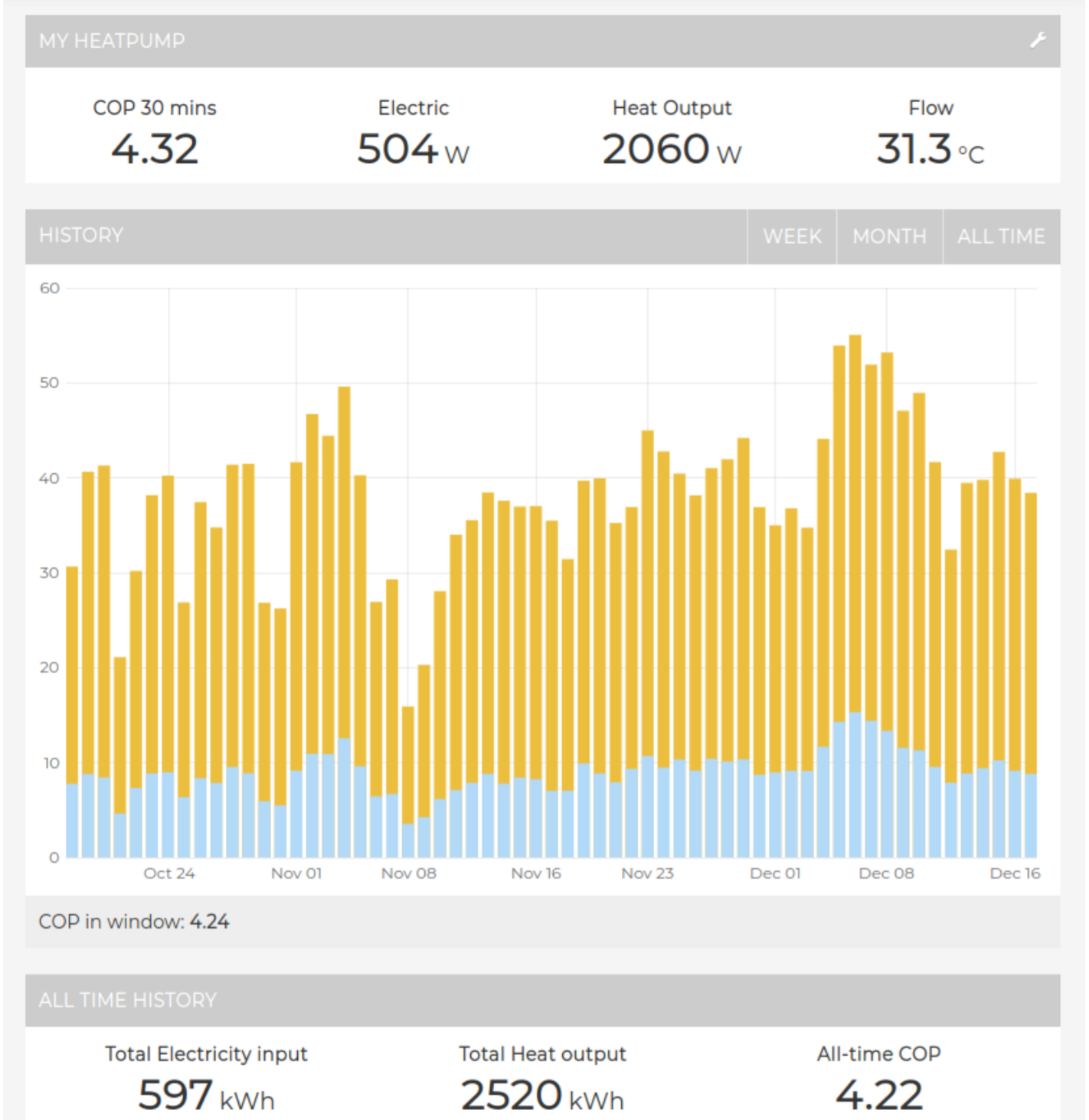

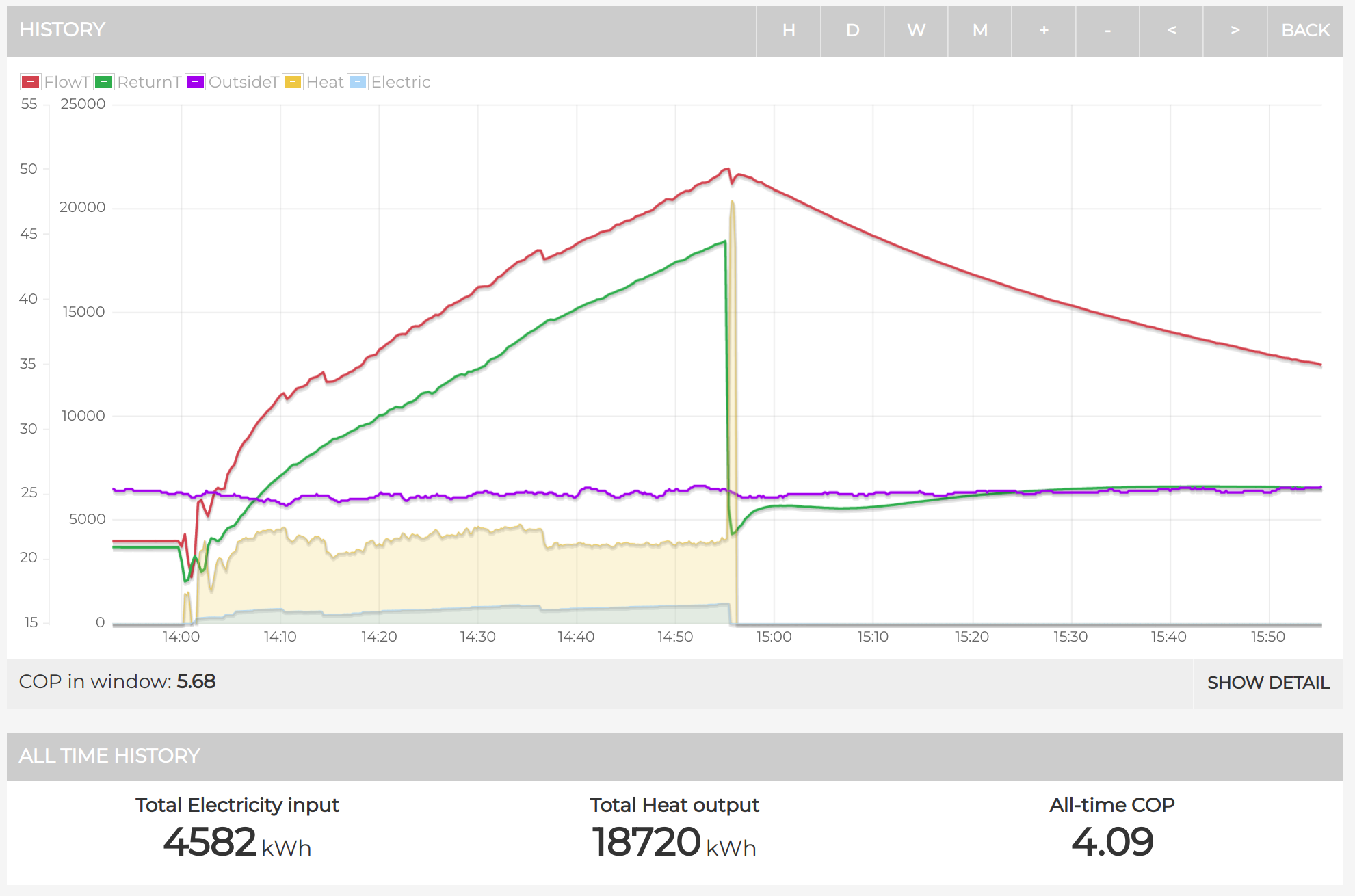

The system is web-connected with remote data access available via emoncms.org, see Live Heat Pump Dashboard Example. Data can be optionally posted to heatpumpmonitor.org.

Bundle Includes

- MID approved Modbus Electricity Meter(s)

- MID approved M-Bus Heat Meter

- emonPi Web-connected data logger WiFi & Ethernet connectivity

- Modbus RS485 reader (for electricity meter(s))

- M-Bus reader (for heat meter)

- Clip-on CT sensor for DHW diverter valve status detection (optional)

- Power supply and cables

- 10yrs of free emoncms.org data logging

Installation Guide

Ideally the monitoring hardware would be installed during the installation of the heat pump, retrofitting is possible but will require draining down at least part of the system to fit the heat meter.

Aug24 onwards: emonHP Setup and user Guide (pdf)

Pre Aug 25: emonHP Setup and user Guide (pdf)

Choice of Heat Meter

A heat meter calculates the heat energy delivered by the heat pump by measuring the flow rate and flow/return temperatures. A heat meter is essential for accurate COP measurement.

All heat meters induce some degree of pressure drop which results in slightly increased pumping power. Larger heat meters have lower pressure drop, but are considerably more expensive. We have tried to recommend heat meters for various heat pump sizes, balancing pressure drop vs cost of the meter. Please do your own calculations to ensure the heat meter is suitable for your application i.e sufficient pump head is available. There is no harm in using a larger heat meter on a smaller heat pump, this will result in lower pressure drop. If using hydraulic separation (buffer or LLH) you may be able to downsize the heat meter since there will be a lot of pump head available from the primary pump.

Our recommended heat meters have a maximum pressure drop of 0.5m, which is approximately equated to 4.5W of additional pumping power on an open-loop system. See our Heat Meter Pressure Drop Spreadsheet and our detailed guide Choosing the Correct Heat Meter for more info.

Glycol: By default, these heat meters DO NOT support the use of glycol. If you're using glycol please contact us.

Choice of Electricity Meter

To calculate COP we need to accurately monitor electrical input. It's important to monitor all the electrical power used by both the outdoor heat pump unit and any indoor pump(s). Depending on how the circuits are configured, this often requires multiple meters.

If the system is open-loop and the primary pump is located inside the outdoor unit e.g Vaillant, Midea, Panasonic, Grant or the indoor controller is back-fed from the outdoor unit e.g Mitsubishi then a single meter can be used.

However, if the system has hydraulic separation and secondary pumps or the primary pump is located indoors e.g Samsung, NIBE then two meters are required.

A third meter can be used to monitor any booster heaters.

We use SDM120 MID approved meters with Modbus output, the meters must be installed inline on the AC circuits.

Connectivity

The emonHP datalogger requires an internet connection. It can be connected via Ethernet or WiFi. We highly recommend Ethernet connection for long term reliability. If Ethernet is not possible, WiFi can be used.

To ensure hassle-free installation please provide WiFi SSID & password, so the unit can be pre-provisioned to automatically connect.

*To enable us to offer remote support the emonHP has remote access enabled by default, this can be disabled on request.

Alternative Fittings

Temperature sensor tees

- 28mm x 28mm x 1/2″ BSP Female Branch Tee (M Press)

- 35mm x 35mm x 1.2" BSP Female Branch Tee (M Press)

Flat face unions

- 1 1/4″ Flat Faced Union Adaptor x 28mm Copper Press Fit unions (M Press) - for DN25 body heat meters e.g QP3.5+

- 1 1/4" Flat Faced Union Adaptor 35mm female solder - for DN25 body heat meters e.g QP3.5+

Live Heat Pump Dashboard Example

Heat Pump Monitor Website

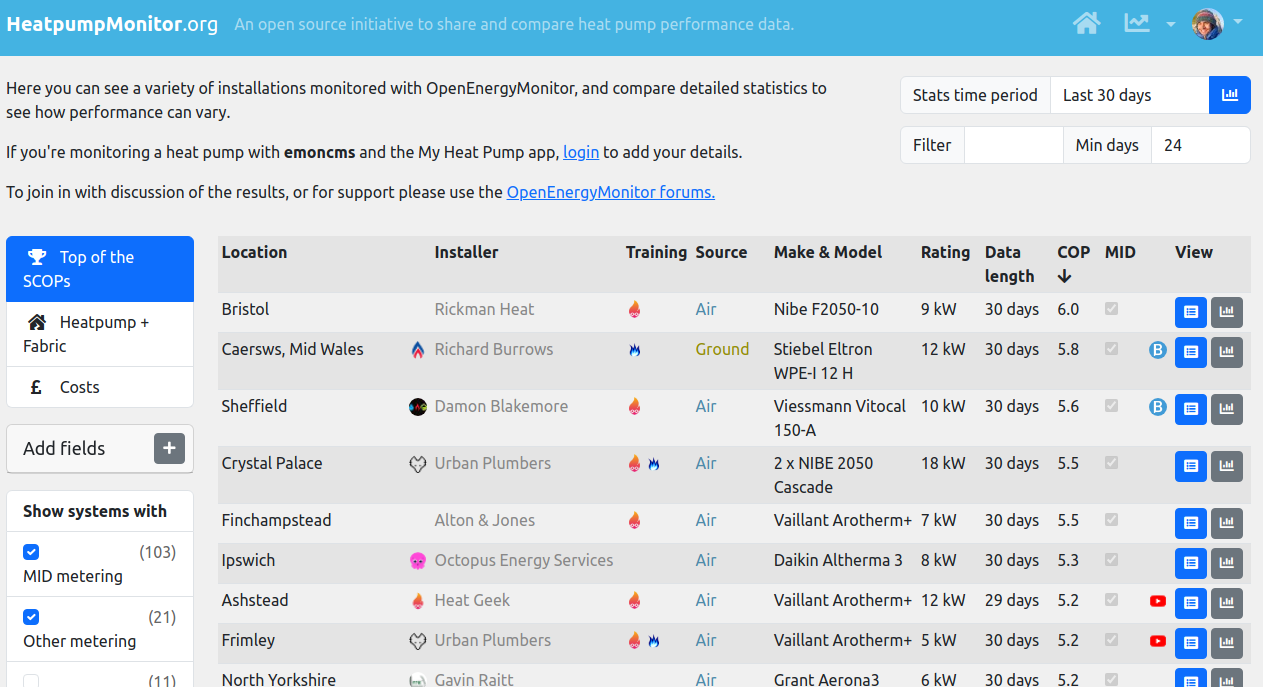

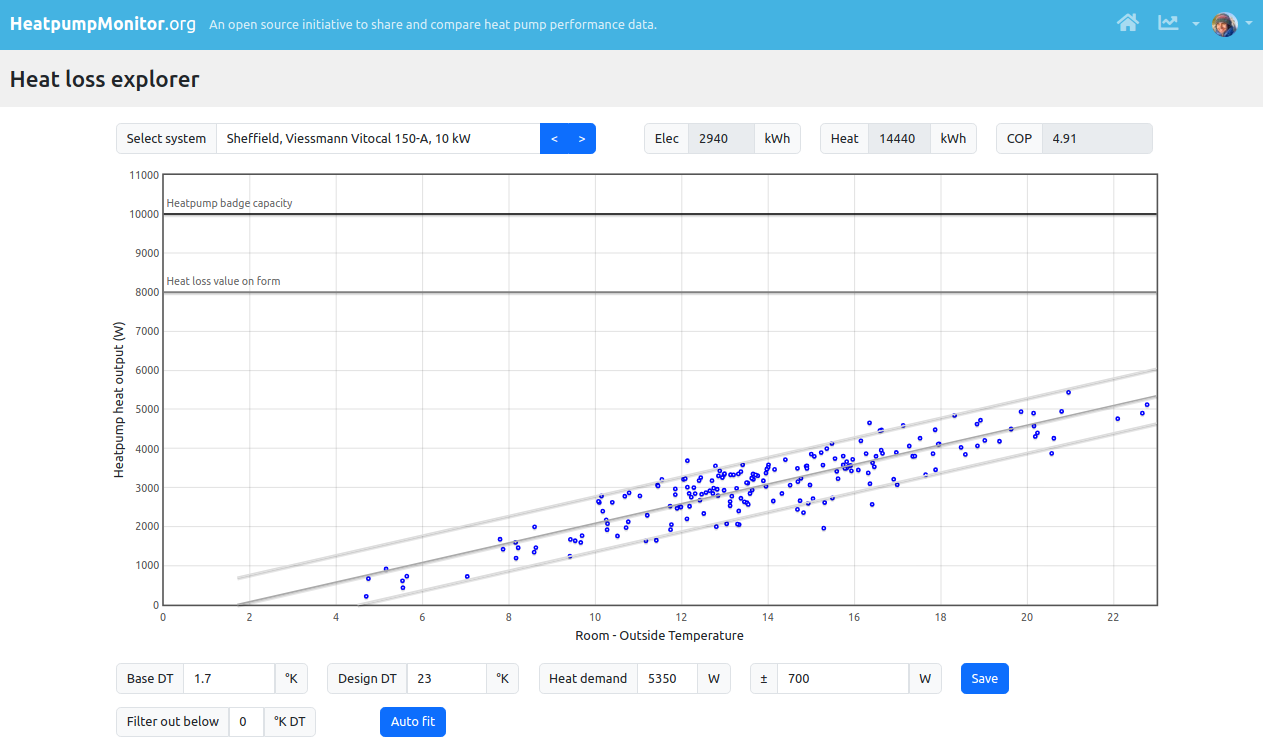

Optionally, you can choose to post the data to https://heatpumpmonitor.org, an open-source community initiative to share and compare real-world heat pump performance data.

To do this, login to heatpumpmonitor.org with the same credentials used by emoncms.org and then click Add New System and fill in the form.

Open source

The system is fully open source with hardware design and software source code available on github:

- Emoncms

- Emoncms MyHeatPump app dashboard

- HeatPumpMonitor.org

- emonPi2

- emonHub Modbus/ M-Bus Interfacer